Have you ever wondered why a 2 x 4 piece of lumber doesn’t actually measure 2 inches by 4 inches? What does that mysterious “B&BTR” stamp mean? Understanding lumberyard lingo is helpful for any DIY enthusiast or homeowner planning a project. In this guide, we’ll demystify the terminology, explain how lumber is processed, and help you navigate the sometimes confusing world of wood.

How Lumber Is Cut and Graded

Before getting into the specifics of lumber terminology, it helps to understand the journey wood takes from forest to lumberyard, which shapes the final product’s characteristics and quality.

Sawmill Basics

Lumber manufacturing begins at the sawmill, which transforms logs into usable boards.

Softwood lumber is typically cut at 2-inch wide intervals (4, 6, 8, 10, and 12 inches) and even lengths (8, 10, and 12 feet). This standardization provides consistency for construction and DIY projects. Hardwoods, however, are cut to whatever width and length the log allows, offering more variety but less uniformity.

The lumber industry often refers to thickness in quarter-inch increments. For example, a 1-inch board is referred to as 4/4 (four quarters), while a 2-inch board is 8/4 (eight quarters).

Drying Process

After sawing, lumber undergoes a drying process. Freshly cut wood, known as green lumber, has a high moisture content that must be reduced before you can use the wood. Here’s how it works:

Lumber is initially stacked with spacer strips between layers to allow air circulation. Some lumber is left to air dry naturally, which can take weeks or months, depending on the climate. To speed up the process, many mills use heated kilns. This method not only dries the wood faster but can also kill any insects in the lumber.

As wood dries, it shrinks in width and thickness. Even after drying, wood continues to expand and contract slightly with changes in humidity. This is why you must account for wood movement when building cabinets, furniture, or other wood structures.

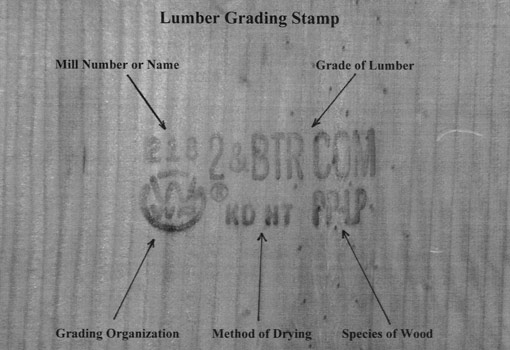

To help buyers understand the moisture content of their lumber and choose the right lumber for their projects, mills stamp boards with drying designations:

- S-GRN (Surfaced Green): Not dried, moisture content over 19%

- S-DRY (Surfaced Dry): Air dried to a moisture content of less than 19%

- KD (Kiln Dry): Dried in a heated kiln to a moisture content of less than 19%

- MC 15 (Moisture Content 15%): Dried to a moisture content of 15% or less

- HT (Heat Treated): Heated to at least 133°F for 30 minutes at the board’s core to kill any insects

Planing

After drying, most softwood lumber goes through a planing process to smooth the wood and create uniform width and thickness. Planed lumber is designated as S4S if it has been surfaced on all four sides or S2S if the edges are left rough.

Planing reduces lumber’s dimensions. One-inch boards are typically planed to ¾ inch, while 2-inch stock is diminished to 1½ inches. Planing also affects width, removing ½ inch from boards 4 to 6 inches wide and ¾ inch from boards over 6 inches wide. This explains why a 2 x 4 measures 1½ inches by 3½ inches.

While you can get unplaned lumber directly from sawmills, it’s called “rough” for good reason. The dimensions can vary from board to board, which might be fine for an unfinished shed but problematic for most other projects where you need consistency.

Hardwood lumber, on the other hand, is often sold rough. This allows cabinet and furniture makers to plane and straighten boards to their specifications, giving them more control over the final product.

Understanding Lumber Grades

Lumber grading is a standardized system that helps buyers understand the quality and characteristics of the wood they’re purchasing. This system considers factors such as knots, splits, and other defects that can affect the lumber’s strength and appearance.

Softwood Grades

Softwood lumber, which comes from coniferous trees like pine, fir, and spruce, is graded based on both appearance and structural integrity. The most common grades for construction lumber are:

- Select Structural: This is the highest grade, with minimal knots and a nearly perfect appearance. This is the best option for high-stress structural applications where both appearance and strength are equally important.

- No. 1: High-quality lumber with some small knots allowed. This grade works for projects that will be visible and need structural integrity.

- No. 2: Standard framing lumber allows for more knots and imperfections but still maintains a balance between strength and workability, making it ideal for most construction uses.

- No. 3: This lumber is lower quality, but still doesn’t allow defects to go all the way through the wood. It’s usable for construction purposes where appearance is less of a concern, often in areas not visible.

For appearance-grade softwood, you might see designations like:

- A Select: Clear with no knots

- B Select: Has a few minor defects, but none too glaring

- C Select: Nearly clear of defects on one face, making it best for applications where one side will be visible while the other stays hidden

- D Select: Small knots or defects throughout

Hardwood Grades

Hardwood lumber from deciduous trees such as oak, maple, and cherry uses a different grading system focused more on appearance than structural integrity. The National Hardwood Lumber Association (NHLA) sets these standards:

- FAS (First and Seconds): The highest grade, with large, clear areas free from defects. It’s often used for fine furniture, cabinetry, and other applications requiring a flawless surface. These boards must be 6 inches or wider and 8 feet or longer, with 83% of the board clear of knots and defects.

- Select: Similar to FAS but with smaller board sizes allowed. This grade is excellent for projects that need a balance between quality and cost. Allows boards as narrow as 4 inches and as short as 6 feet.

- No. 1 Common: Allows for more knots and defects. Often used for cabinet- and furniture-making, providing an appearance with character without sacrificing too much usability. Must be a minimum of 3 inches wide and 4 feet long with 67% of wood clear from knots.

- No. 2 Common: More defects allowed—often used for flooring or pallets where the surface imperfections can add a unique look. It must be at least 50% clear of knots.

Decoding Common Lumberyard Terms

When visiting a lumberyard, you might encounter a variety of terms and abbreviations. Here’s a quick guide to some common lumberyard lingo:

- B&BTR (B and Better): This indicates lumber that meets or exceeds B-grade standards, ensuring a higher quality with fewer defects.

- VG (Vertical Grain): Lumber cut so that the growth rings are nearly perpendicular to the face of the board, providing a uniform appearance and better stability.

- PT (Pressure Treated): Lumber treated with preservatives to resist decay and insects—ideal for outdoor projects where exposure to elements is a concern.

- MDF (Medium Density Fiberboard): An engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, offering an alternative to solid wood with consistent density and stability.

Choosing the Right Lumber for Your Project

Choosing lumber for your project comes down to a few factors: whether it’s for indoor or outdoor use, how strong it needs to be, your budget, and how dry the wood is. For outdoor projects, go with pressure-treated wood or naturally durable options like cedar or redwood so it stands up to the elements. If you need lumber for something structural, make sure it’s strong and graded for safety. On the other hand, decorative pieces can focus more on looks. Balancing what you need and what you can afford is key to getting the best results without overspending.

Moisture content is also important, especially for indoor projects. Using properly dried wood helps prevent warping or splitting later. If you’re ever unsure about what to pick, don’t hesitate to ask for help at the lumberyard. The staff there usually know a lot about different types of wood and can give you tips to make sure your project turns out just right.

Leave a Reply